Search This Supplers Products:Chainsawlawn moverearth augertillerbrush cuttergenerator

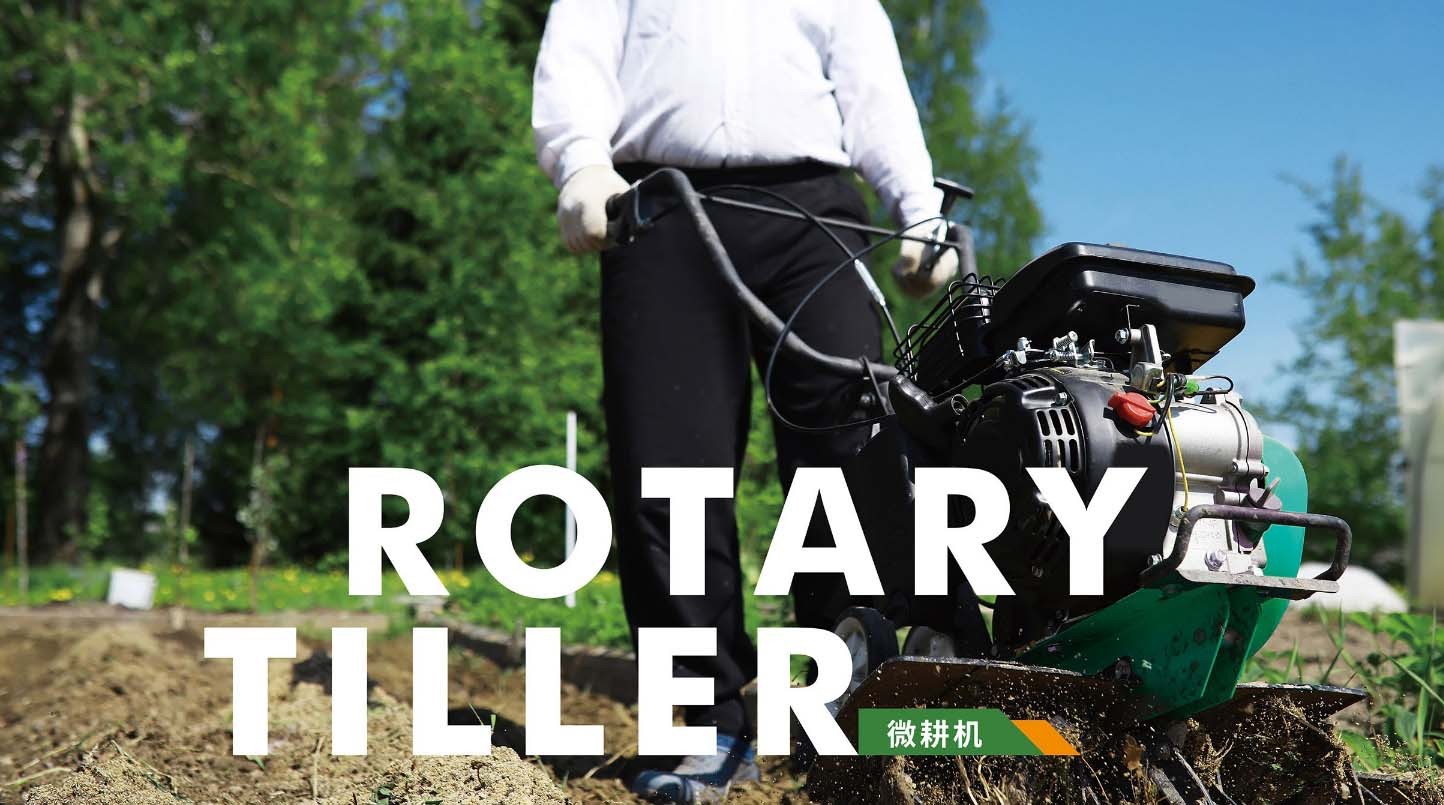

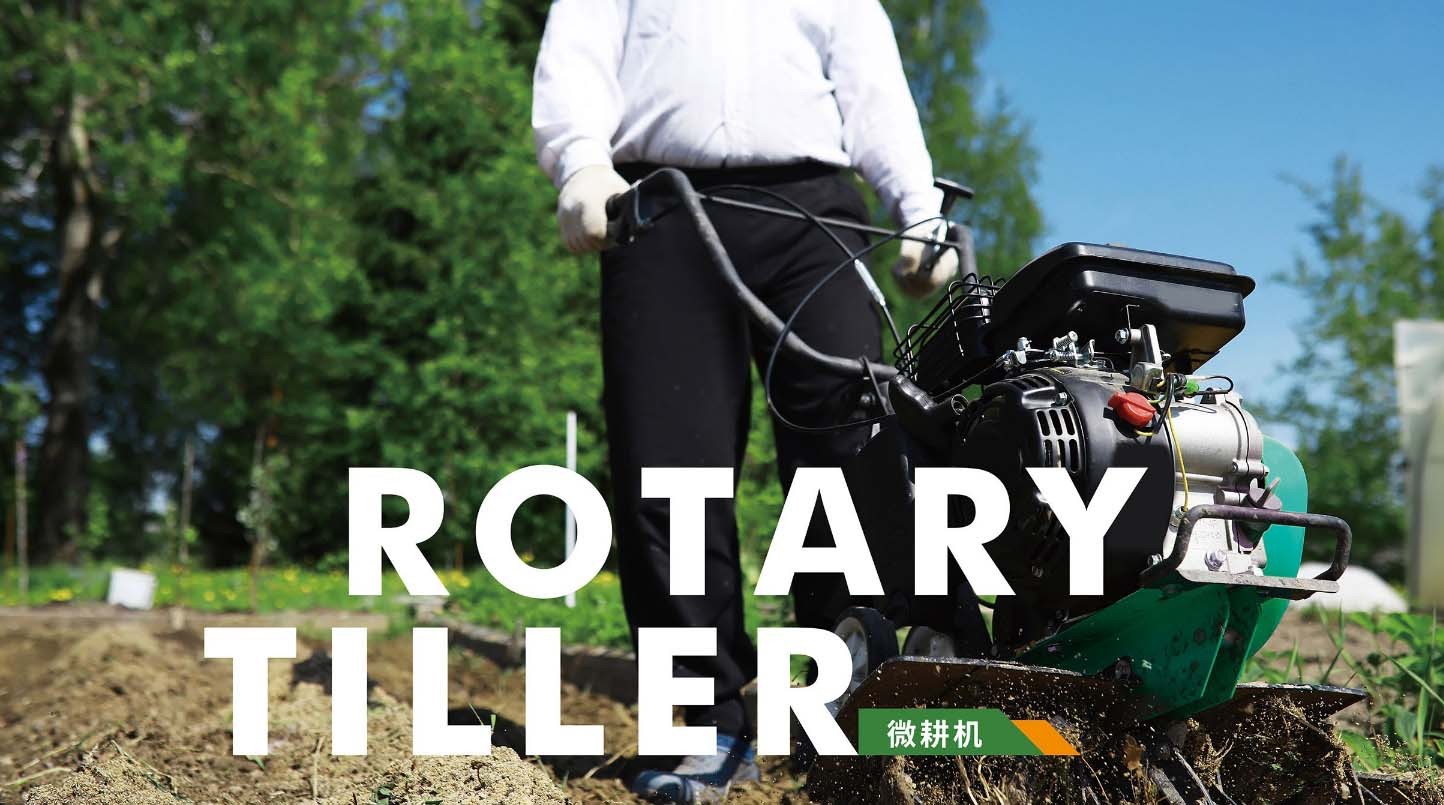

Why the micro-tiller did not turn: the reason and the solution

time2023/10/21

- In farmland operations, the micro-tiller is a common farm tool, which can help farmers more efficiently in agricultural activities such as farmland, planting and irrigation.However, sometimes we will encounter the situation that the micro-tiller does not turn, which will seriously affect the agricultural production schedule.So, why not did the micro-tiller turn?This article will reveal the causes and solutions to this problem.

I. Why didn't the microtiller turn around?

1. Motor failure: the motor of the micro tiller is the core component to drives its operation.If the motor failure, such as line short circuit, serious bearing wear, etc., will lead to the micro-tiller can not rotate normally.

2. Transmission mechanism failure: the transmission mechanism of the micro-tiller includes gear, chain and other parts, which are responsible for transferring the power of the motor to the tillage parts.If the transmission mechanism failure, such as gear wear, chain falling off, etc., it will also lead to the micro-tiller can not turn.

3. Soil resistance is too large: in the process of farming, if the soil is too hard or there are a large number of stones, it will increase the resistance of the micro-tiller, so that it is difficult to rotate normally.

4. Equipment overload: if the micro-tiller is overloaded, it will lead to difficult rotation, and even burn the motor.

II. problem analysis:

1. Motor failure: this may be due to long-term use of line aging, bearing wear and other reasons, may also be caused by short circuit caused by improper operation.

2. 2.Transmission mechanism failure: usually due to the long-term working in the harsh environment, resulting in the gear, chain and other parts wear seriously, or due to the failure caused by improper maintenance.

3. Soil resistance is too large: this is mainly due to the poor soil conditions, such as too hard or the existence of a large number of stones, resulting in the rotation of the micro-tiller difficulties.

4. Equipment overload: it may be caused by overload use, or improper operation.

III. resolvent:

1. Motor fault: it is necessary to check whether the lines and bearings of the motor are normal, and they should be replaced or repaired if necessary.At the same time, the motor should be maintained and maintained regularly to extend its service life.

2. Transmission mechanism fault: you need to check whether the gear and chain of the transmission mechanism are normal, and it should be replaced or repaired if necessary.At the same time, the transmission mechanism should be maintained and maintained regularly to extend its service life.

3. Soil resistance is too large: the soil should be pretreatment before tillage, such as soil loosening, removing large stones, etc., to reduce the resistance of the soil to the micro-tiller.

4. Equipment overload: should avoid the overloading of micro-tiller, and should pay attention to the operation specifications, to avoid overload caused by improper operation.

IV. Matters need attention:

When using the micro-tiller, attention should be paid to keep a safe distance to avoid injury due to improper operation.At the same time, the micro-tiller should be checked and maintained regularly to ensure its normal operation.In the case of the micro-tiller does not turn, it should be analyzed and treated according to the specific situation, do not blindly disassemble or replace the parts.

V. conclusion:

Why the micro-tiller does not turn is a common problem, its reasons mainly include motor failure, transmission mechanism failure, excessive soil resistance and equipment overload.To solve this problem needs to be analyzed and handled according to the specific situation, but we need to keep a safe distance and follow the operating specifications.Do not blindly remove or replace the parts when encountering problems, but should seek for professional help.